Truecore Steel Technical Guide

The Ultimate Guide to TRUECORE® Steel Framing

Before you choose the benchtops and basin, the windows and blinds, and the doors and floors, select the one thing that genuinely supports the whole house: the frame.

A building frame made from BlueScope's TRUECORE® steel is strong, straight and precise, won't twist or warp over time and won't catch fire.

And TRUECORE® steel is termite and borer proof – so it's no wonder that the inner strength of TRUECORE® steel is the future of house framing and trusses.

Key benefits of using TRUECORE® steel frames and trusses:

-

TRUECORE® steel is 100% termite and borer proof.

It's not treated with insecticides to keep termites from eating your frame, so it is an ideal choice for those seeking to minimise the use of insecticides in their home.

TRUECORE® steel won't ignite or contribute to the spread of house fire, giving you added peace of mind.

-

House frames made with TRUECORE® steel are straight, true, and built to stay that way.

TRUECORE® steel won't shrink, twist or warp over time, so there's less chance of sticking windows, jammed doors, and wavy roof and wall lines.

TRUECORE® steel has a reassuring warranty of up to 50 years for eligible applicants.

-

House frames made with TRUECORE® steel are an excellent choice for modern Australian homes.

Their impressive strength-to-weight ratio allows for wide spans and contemporary open-plan design to suit comfortable family living.

-

TRUECORE® steel is proudly manufactured in Australia by BlueScope, the manufacturer of COLORBOND® steel.

You can rest assured that all TRUECORE® steel is made to all relevant Australian Standards and rigorously checked for quality and consistency.

THE FAMILY HOME IS YOUR BIGGEST INVESTMENT, AND YOU ONLY GET ONE CHANCE TO BUILD IT RIGHT

That is why more and more Australian homeowners choose the distinctive blue house frames made from TRUECORE® steel. Recently featured on The Block, TRUECORE® steel delivers a great start to a beautifully finished home.

When building, consider the following points:

TRUECORE® steel with Activate® technology is an aluminium/zinc/magnesium alloy coated structural steel with a distinctive blue resin surface finish.

It's used in residential house framing and building frames for mid-rise buildings, including multi-unit dwellings, schools and aged care facilities.

1. How confident are you if offered an equivalent product?

TRUECORE® steel combines the superior strength of zinc/aluminium alloy-coated steel with an exclusive blue resin tint from BlueScope.

TRUECORE® steel complies with Australian Standards AS 1397, and its durability and performance are backed by a warranty*.

2. Benefits of TRUECORE® steel, only from BlueScope

High corrosion resistance

Guaranteed material strength of G550

Warranty* against structural failure caused by corrosion up to 50 years

Proven customer and in-field response and support

Nationwide availability and support

Certified and tested by SIRIM

3. How to identify genuine TRUECORE® steel, only from BlueScope

To identify genuine TRUECORE ® steel made only by BlueScope, pay attention to the TRUECORE ® steel branding text on every coil. The brand presence is your assurance of BlueScope's commitment to quality.

The quality assurance and warranty* offered from BlueScope

Guaranteed minimum yield strength of G550 MPa

Minimum coating mass of 150g/m2 by triple spot test

Nothing less than the original TRUECORE® steel.

This simple checklist is your guarantee of our TRUECORE® steel superiority.

Dimensionally stable

Durable, strong & lightweight

Termite proof

Environmentally-friendly

50 years BlueScope warranty*

Manufactured only by BlueScope

What is Structural Integrity?

“Structural integrity affects the building’s function and safety. Some framing materials are prone to warp, sag or shrink over time, increasing the risks of cracked walls, jammed doors and waving rooflines. Framing materials made from steel are an investment for your building’s future.”

Dimension Accuracy

TRUECORE® steel is true, straight and resistant to deformation.

How Does It Work?

TRUECORE® steel is inert to moisture attack, including any other defects such as fungal growth or termite infestation.

How Does It Perform?

TRUECORE® steel is much easier to utilise because it is flexible in design and provides structural versatility. Framing made from TRUECORE® steel is quick and easy to erect due to prefabrication and fastening techniques.

Other Advantages

Termite proof - TRUECORE® steel is resistant to insect infestation, and hence, there is no damage to the building, with the structure remaining as it is.

No preservative or post-treatment - TRUECORE® steel does not require any post-treatment to prolong service life and minimum maintenance cost.

KEY NOTES:

Certain framing materials are highly sensitive towards moisture and will shrink, twist, rot, warp and damage.

TRUECORE® steel is flexible in design with simple and quick installation.

TRUECORE® steel is a ferrous metal; it is inert to moisture and termite attacks.

What is Structural Design?

Structural design for roof trusses is carried out using Computer Aided Design (CAD) in compliance with relevant design codes such as BS 5950 part 5 or AS/NZS 4600 and other codes of practice as required by local authorities. A typical roof truss system should consist of a top chord, bottom chord, web and batten made from high-strength structural steel grade material with high corrosion resistance performance.

G550–High strength

TRUECORE® steel is a designed structural grade building material with a standard chemical composition and specific consistency in strength. TRUECORE® steel is high tensile and comes with a guarantee of 550 MPa yield strength.

How Does It Work?

TRUECORE® steel can form a specific shape or cross-section. With high tensile strength and the optimised engineering design, the structural load can be handled with less support and larger spans.

How Does It Perform?

TRUECORE® steel is light; thus, it is easy to handle, including steel frame erection that requires minimum lifting cost. The structural load is optimised with less building material, reducing the overall structural cost. This also contributes to quick installation and higher operating efficiency.

Other Strengths

Non-combustible - TRUECORE® steel is non-fire propagated, hence minimum fire risk up to 300 degrees Celsius.

High in durability - TRUECORE® steel, when used properly, will have a service life of a minimum of 50 years.

KEYNOTES:

More timber trusses are required for a traditional build to support the structural load to prevent structural failure.

TRUECORE® steel has high tensile strength that can handle the structural load more effectively with less support.

TRUECORE® steel is specially designed as a high-strength structural grade building material.

What is Corrosion?

Corrosion is caused by the deterioration of metal due to chemical reactions, resulting from environmental exposure (water and oxygen). It is also known as oxidation. Corrosion of metal results in the formation of rust or oxides in the corroded area.

ZN/AL coating technology (AZ150)

BlueScope's proprietary metallic coating technology - TRUECORE® steel, is superior in corrosion performance under varied conditions compared to other galvanised steel. TRUECORE® steel comprises 43.5% zinc, 55.0% aluminium and 1.5% silicon. The minimum coating mass of 150 g/m2 offers high corrosion resistance.

How Does It Work?

Sacrificial protection is provided by an active metal (e.g. zinc), protecting a less active metal (e.g. steel). The more active metal corrodes in preference to the less active metal will corrode. TRUECORE® steel exhibits a more complex coating structure consisting of zinc-rich and aluminium-rich areas. The zinc-rich area provides excellent sacrificial protection, while the aluminium-rich area provides durable barrier protection. These two characteristics make TRUECORE® steel durable and effective against corrosion.

Corrosion rates of galvanised steel and 55% Al-Zn alloy coated steel at Australian Atmosphere Exposure Test Sites.

Cross-Section Of TRUECORE® Steel

KEYNOTES:

Corrosion is the dissolution of metal due to the surrounding environment.

TRUECORE® steel comprises 43.5% zinc, 55.0% aluminium and 1.5% silicon with a minimum coating mass of 150g/m2.

For TRUECORE® steel, the zinc-rich area provides excellent sacrificial protection, while the aluminium-rich area provides durable barrier protection.

TRUECORE® STEEL Data sheet

Green accreditation for the environment

Environmental sustainability is a continuous effort and commitment from all of us. We ensure our customers receive the highest standard in both quality and efficiency with the environment's best interest at heart. There is no better way to demonstrate our commitment than receiving green accreditation from renowned independent bodies.

Truecore coated steel products are accredited with Eco-Label by SIRIM QAS International, a member of the Global Ecolabelling Network (GEN).

The SIRIM Eco-Label certification identifies a product's overall environmental impact and the communication of its environmental information to consumers and businesses. Through this scheme, the product has undergone independent evaluation. It is certified by SIRIM on its environmental performance against criteria that include the composition of raw materials used, hazardous substances management and waste and energy management in the entire manufacturing operation cycle.

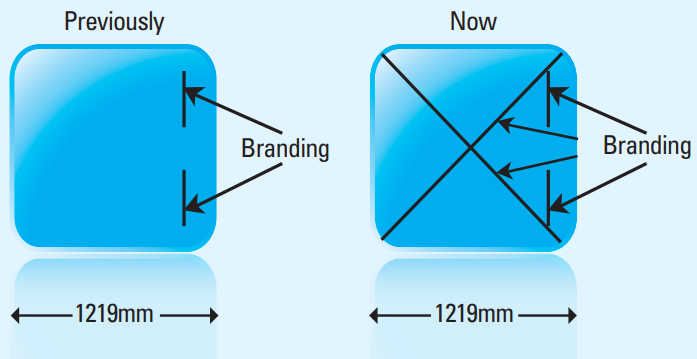

How to identify genuine TRUECORE® steel? To identify that your TRUECORE® steel is genuine from BlueScope, look for this branding text on every coil and its distinctive blue-tinted resin appearance.

TRUECORE® Steel FAQs

-

To maximise the identity of TRUECORE® steel, both side branding and sinusoidal branding co-exist in TRUECORE® steel. See the illustration below.

-

No. Sinusoidal branding is just a change with the printing orientation, and there is NO impact on the product performance and the mechanical properties. TRUECORE® steel still guarantees minimum yield strength of 550 MPa.

-

No. After TRUECORE® steel has been slitted, the sinusoidal branding text will be cut into small portions. You may see only a part of the branding text in diagonal directions in every slit piece or every truss. See the illustration below.

-

No. The objective of reverse sinusoidal branding text is to increase the visibility of TRUECORE® steel's branding text for easier identification. However, if its content is wrongly printed, such as wrong coating mass, e.g. AZ100 instead of AZ150, then a formal complaint could be raised.

-

Although you are seeing only a portion of the branding text, the diagonal direction of the branding text is now a unique product identification feature of TRUECORE® steel, where imitated blue tinted steel products will not be able to replicate.

When your reputation relies on delivering beautifully finished projects, start your build right by specifying frames made from TRUECORE® steel.

Frames made from BlueScope's TRUECORE® steel are strong, straight and true, won't twist or warp over time and won't catch fire. They're also termite and borer-proof and offer design flexibility, so it's no wonder that the inner strength of TRUECORE® steel is the future of framing.

We’re the leading suppliers and manufacturers of steel frames and steel roof trusses across Newcastle and the Central Coast. Our state-of-the-art facility on the Central Coast is equipped with the latest in innovative steel framing technology.

Contact us today to learn more about TRUECORE® steel framing or to request a quote.